- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Curry Publish Time: 2024-02-29 Origin: Site

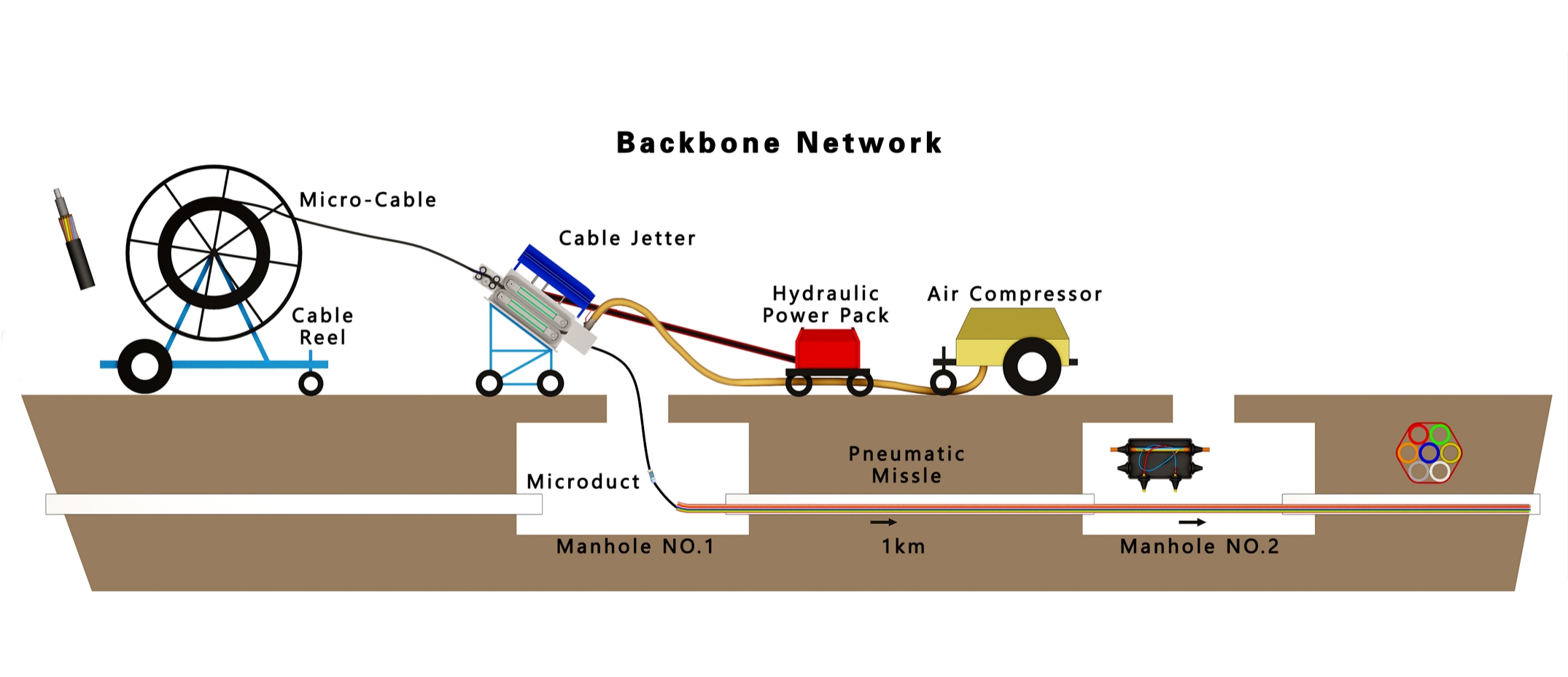

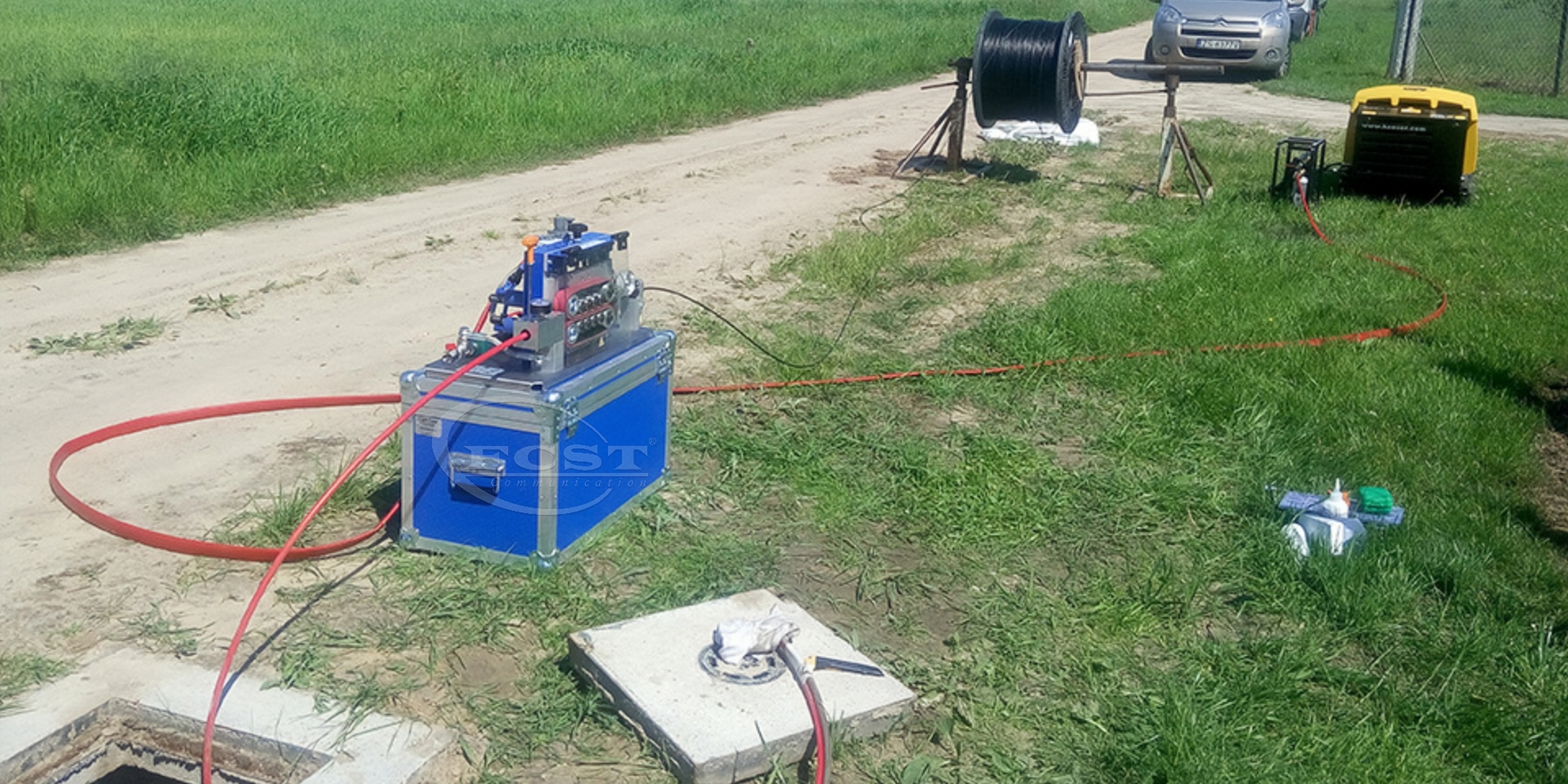

Fiber cable blowing is a safe and effective optical cable laying method. During the cable laying process of the cable blowing machine, the traction force of the dragger, the blowing force of the compressed air and the thrust of the conveyor belt act on the optical cable at the same time. Therefore, an air compressor is needed to assist the work of the cable blower.

The Working Principle Of Fiber Cable Blowing

The two key equipment for laying air blown fiber optic cable by cable jetting are cable blowing machine and air compressor. The air compressor generates compressed air and sends it to the sealed cavity of the fiber blower through the air hose. The lead-out end of the silicon pipe is connected with the sealed cavity of the cable jetting machine. The dragger used to pull the optical cable is placed in the tube together with the air-blown optical cable. The rubber around the dragger is sealed with the inner wall of the tube, and the sealed container formed is connected to the sealed cavity of the cable blowing machine. Therefore, the pressure generated by the compressed air pushes the dragger to pull the optical cable forward in the tube. The air compressor continuously supplies air to ensure that the force exerted on the dragger is basically constant, thereby ensuring that the force exerted on the air blowing micro cable is basically constant. At the same time, the compressed air flows forward. On the one hand, it exerts force on the optical cable to push the optical cable forward. On the other hand, the optical cable is suspended in the tube, which reduces the friction between the cable and the inner wall of the sub-tube during laying, and maximizes the protection of the optical cable. fiber optic cable. The high-pressure gas generated by the air compressor is quickly sent to the fiber blowing machine through the connecting hose, driving the pneumatic motor of the cable blower, driving the upper and lower conveyor belts to rotate, and the optical cable is placed between the upper and lower conveyor belts, thus pushing the optical cable forward.

Technical Points Of Fiber Cable Blowing

1.The fiber blowing equipment must be of a model suitable for the characteristics of the project. The air pressure at the compressor outlet should be maintained at 0.6~1.5MPa, the air flow should be greater than 10m³/min, and the cable blowing machine should be hydraulically driven (or air flow driven). The propulsion force of the device should meet the requirements.

2.Before blowing the air blown fiber cable, the pipeline should be tested for air retention and continuity, and the cable should be blown only after confirming that the pipeline is not damaged, leaking, sprained, and free of dirt and other debris.

3.Cable blowing lubricant should be added into the pipe before blowing the cable. The amount added is determined based on the smoothness of the inner wall of the pipe hole, the complexity of the pipeline path, the length of the cable blowing, the type of lubricant, etc. The amount of lubricant added is directly related to the length and speed of the blowing cable.

4.When the pipeline path has a large gradient, the piston cable blowing head laying method should be used to increase the traction force of the front section of the optical cable.

5.When the conduit is relatively flat, but there are large bends in certain sections of the pipeline, the piston-less cbale blowing head laying method should be used.

6.The optical cable should be cleaned continuously during the blowing process to prevent mud and water from entering the pipe along with the optical cable and increasing the friction force.

7.The blowing speed of the optical cable should be controlled between 60 and 90m/min, and should not exceed 100m/min, otherwise the construction personnel are not easy to operate, and it is easy to cause optical cable sprain.

8.During the cable jetting project, if the pipe fails to blow in or the speed is extremely slow (below 10m/min), the fault location should be found first and treated before blowing to prevent damage to the optical cable or cable blowing equipment.

9.When blowing cables, special personnel must be installed at the opposite end of the pipeline to protect and maintain communication to prevent the test rod, air blower and other objects from blowing out and injuring people. Protective personnel should also do a good job in preparing the optical cables after they are blown out.

10.Safety should be ensured when the optical cable is blown or placed in the "8" reserved coil. The bending radius should not be less than the specified requirements.

FCST - Better FTTx, Better Life.

We have been designing, manufacturing and supplying passive components for fiber optical networks since 2003. Everything we do in FCST is designed to provide efficient, simple and innovative solutions to solve complicated tasks.

We offer 4 solutions

lFTTH ODN Solution

lUnderground Cable Installation Solution

lAerial Cable Installation Solution

lFiber Tools & Test Solution

As a FTTx solution supplier, we can also do ODM according to project. We will continue to innovate and contribute more to the construction of the global optical fiber network.